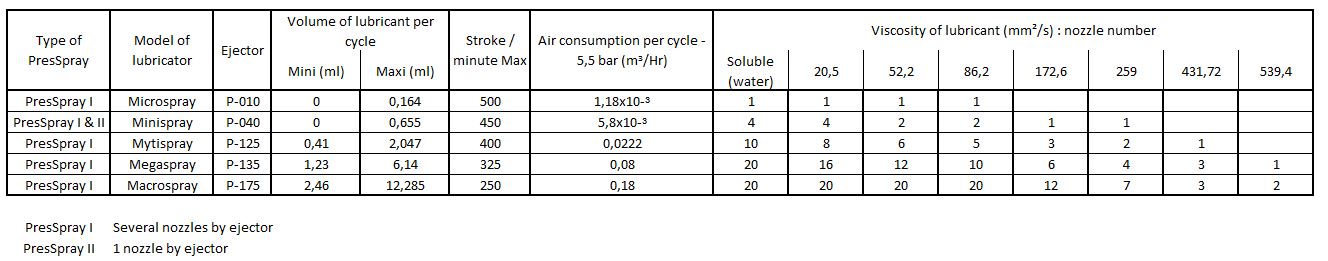

PresSpray I – Airless spray lubrication :

LSP’s original airless spray lubrication system, the PresSpray I is the economical solution to die lubrication. The PresSpray I is a versatile system with elements of customization and can be purchased as a bracketed module for easy installation.

PresSpray II – Airless spray lubrication systems with individual nozzle control :

A high pressure airless spray lubrication system with individual volume and velocity control to each nozzle. The basic design of the PresSpray II is simple but functional. The PresSpray II uses positive displacement pumps to dispense lubricant in a fine airless spray. The systems come prepackaged so that the end user can install it in minutes. PresSpray II systems are flexible with the ability to add up to 12 ejectors per system.

How the PresSpray I works :

The LSP PresSpray I uses positive displacement pumps for lubricating dies in metal stamping presses. It dispenses lubricant into either the die area of a punch press or on the coil stock prior to it entering the die area. The lubricant is dispensed in a predetermined quantity, in a fast-instantaneous spray that evenly coats the designated area. One ejector can handle multiple nozzles all dispensing in unison. Heavy duty construction allows it to handle heavy viscosity lubricants as well as light viscosity lubricants.

How the PresSpray II works :

Each nozzle is controlled by a separate Ejector. When an actuator switch is tripped either electrically or manually the Univalve air valve dumps air into an air manifold triggering all assembled ejectors. The nozzle spray patterns are individually controlled with the volume and velocity controls on each ejector.