The Push-pull system is powered by a hydraulic motor located inside the table.

It is fitted out with hooks to grab the tools with easy adjustment and clamping of the hooks position.

2 long hooks are used for the positioning of dies up to 350 mm long, into the press bolster and 2 others short hooks are used for deeper tools.

A sensor located in the table detects its correct positioning, in front of a press bolster or a storage rack.

When is in position :

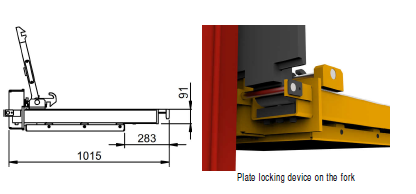

This table can be easily assembled (or dismantled) on your standard forklift, thanks to :

Tool hook must be set-up on each tool (sold separately).

Press table and storage rack must be fitted out with pair of plate attachment (sold separately).

LIFTMATIC TPI ON BOARD DRIVER :

| Reference |

Tool maxi weight (kg)

|

Tool maxi PU (mm)

|

Tool maxi LU (mm)

|

Plate LU (mm)

|

||||

|---|---|---|---|---|---|---|---|---|

| Liftmatic TPI 10.600 | 1000 | 600 | 1400 | 820 | ||||

Accessories

|

||||||||

| Liftmatic TPI 10.800 | 1000 | 800 | 1400 | 820 | ||||

Accessories

|

||||||||

| Liftmatic TPI 20.600 | 2000 | 600 | 1400 | 820 | ||||

Accessories

|

||||||||

| Liftmatic TPI 20.800 | 2000 | 800 | 1400 | 820 | ||||

Accessories

|

||||||||

|

|

|||

|

|

|||

|

|

|||

|

|

|||